Hot sale Float Glass Production Line - Glass Laminating Furnace for Architectural Glass and Decorative Glass – leader

Hot sale Float Glass Production Line - Glass Laminating Furnace for Architectural Glass and Decorative Glass – leader Detail:

Product advantages

1.Leader glass laminating furnaces are exported to over 40 countries in Europe, America, Asia, Africa and Oceania. We have the biggest production workshop in China.

2.very accurate temperature controlling system.the temperature difference inside the furnace is aobut only 1-2 degrees. Using our machine, there is no questions that laminated glass is heated excessively or heated not enough. So there is not problem that laminated glass has more glue overflow or transparence is very bad.

3 . Good materials with famous electric appliance. Even in the future need change some spare parts, it is easy to get the supplier and don’t worry that can not find the substitute.

4 . Longer expiration time and update service in the whole of lifetime.

5.We accept customization, we have very mature technical team

Technical parameter

| Style | LD-M-4-2 |

| Electric power | 3 Phase, AC 380V,42KW |

| Processing glass size

|

Max : 2440x3660mm Min:50x50mm |

| Arched glass height: 360mm (Max) | |

| Glass thickness: 40mm(Max)/2mm(Min) | |

| Capacity

|

Process Cycle: 40-120 Minute/ Furnace |

| Max processing area:53 Square meters/Furnace(Max) | |

| Exterior dimension | About 10500L*4500W*1100H(mm) |

| Working temperature | 90℃-140℃ |

| Net weight | About 3100Kgs |

Operation steps

Step 1

Prepare the glass and EVA film.Select the appropriate size of glass,make sure that the glass is clean and dry.Then put the glass on the combination table to combine the glass with the film.Fix the glass well with high temperature tape.

Step 2

Put the glass between the high temperature cloth and seal the silicone vacuum bag well.Then vacuum

Step 3

Push the tray into the heating chamber and vacuum again.

Step 4

Set appropriate parameters according to the thickness and type of glass.

Step 5

The machine will automatically vacuum and heat, and stop automatically after completion.We can take out the glass from the vacuum bag after it cools slightly.

Application

1. Architectural Laminated Glass

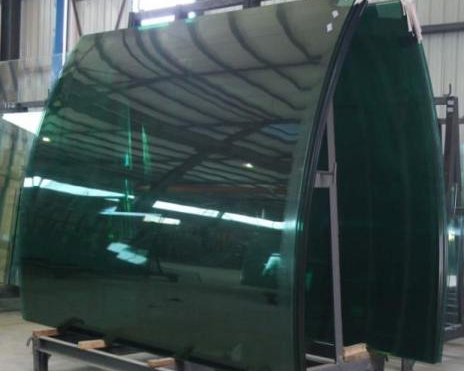

2. Building curved laminated glass

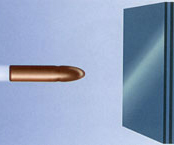

3. Bulletproof glass

4. Real flowers &feather&leaf laminated glas

5. Wire and cloth laminated glass.

6. Colored film laminated glass

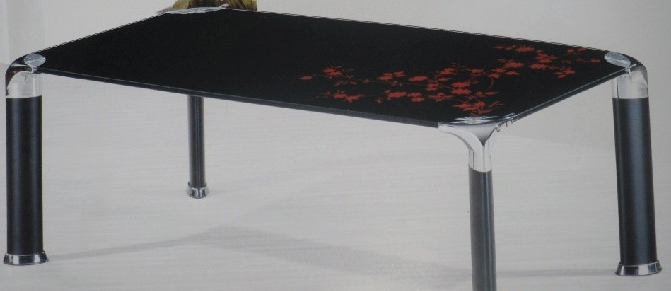

7. Coffee table glass and window glass of cabinet

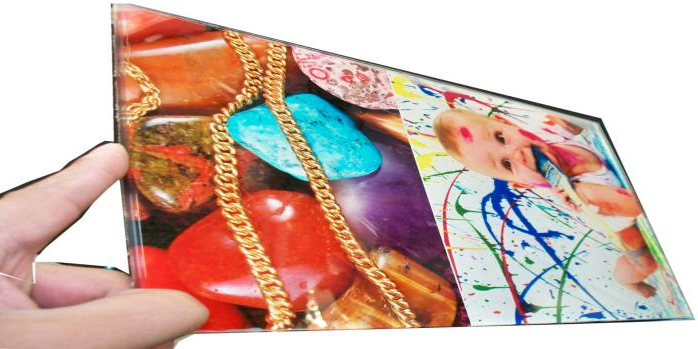

8.Photo and picture laminated glass.

9. Tempered lamianated glass and closet doors.

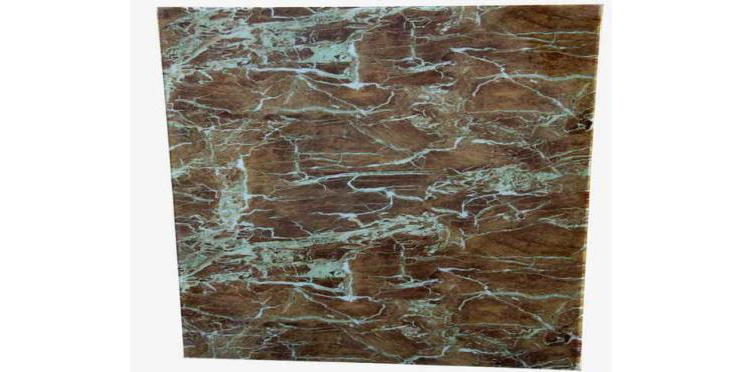

10. Marble laminated glass

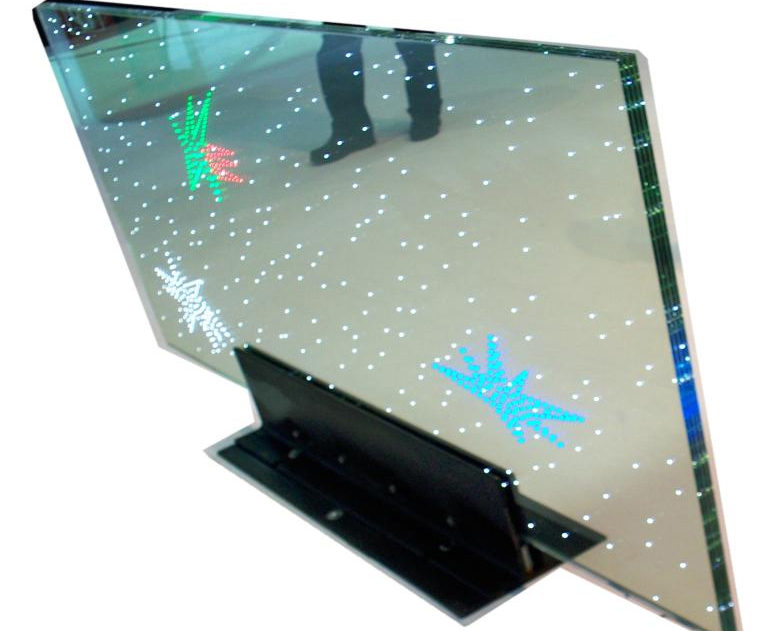

11. Solar PV panels laminated glass, LED glass and electric glass.

12. Polyvision privacy glass

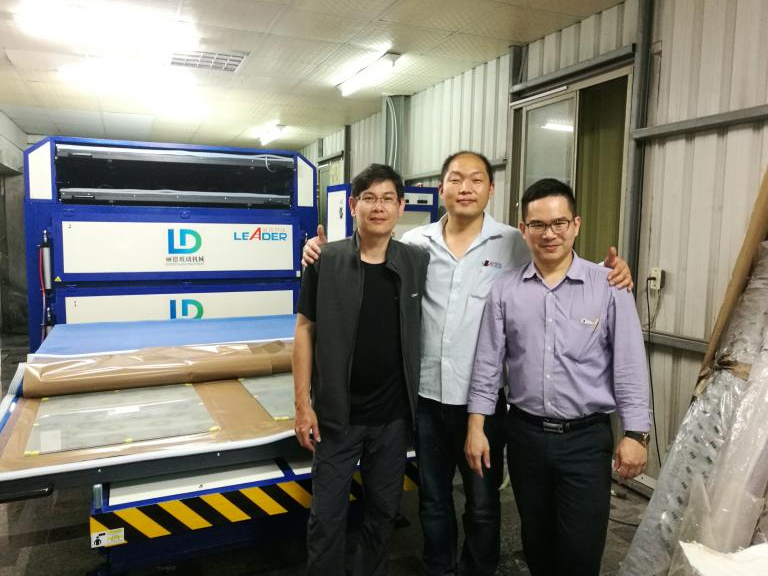

Workshop

Loading pictures

Customer plant

Customer satisfaction

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Hot sale Float Glass Production Line - Glass Laminating Furnace for Architectural Glass and Decorative Glass – leader , The product will supply to all over the world, such as: Eindhoven, Burundi, San Diego, We welcome customers from all over the world come to discuss business. We supply high quality products, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!