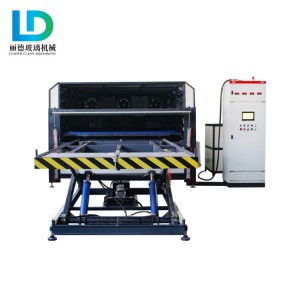

Tempered Glass Heat Soak Furnace

Features

1.The tempered glass heat soak furnace is designed and manufactured according to the European testing standard for reinforced glass safety performance.

2.The process parameters and program control make use of the computer memory storage and intelligent control.

3.The temperature adjustment mode is automatically completed by the electric control system based on Kingview.Temperature curve is automatically stored,you can print the test report of every furnace.

4.Hot air forced convection system is made up of 12 sets of fans in the furnace, in addition,4 sets of fans are used for the cooling of the automatic control unit.

5.The thermocouples in the furnace are used to monitor the temperature of the glass surface in different areas, which are displayed in real time on the computer. 12 thermocouples on the furnace top can monitor the temperature of each area.

Technical parameter

| Max.glass size | 2500X6000MM |

| Capacity | 6000KGS |

| Max. heating temperature | 320℃ |

| Heating power | 275KW |

| Total installed power | 290KW |

| Power Supply | 3PH/AC380V/220V/50HZ |

| Gas source | 0.6~0.8MPa/1500Lpm |

| Furnace inner size(L*W*H) | 6100x1680x2650MM |

| Overall dimension of main body(L*W*H) | 6400x2200x3680MM |

| Min. workplace size(L*W) | 13*5M |

| Weight | 10T |

Loading pictures

Customer satisfaction